Connecting the wor1d with quality

+86 132 9835 3566Call to get professional solutions for you pipeline projects

Call to get professional solutions for you pipeline projects

1. Dia: DN50-1400mm (2 inch-56 inch).

2. Pressure Class: SDR17, SDR13.6, SDR11, SDR9, SDR7.4, SDR6.

3. Pressure Class: PN10, PN12.5, PN16, PN20, PN25, PN32.

4. Packing: Packaged by cartons or bags.

5. Delivery: 5-10 days depending on the total quantity.

6. Product inspection: Raw material inspection. Finished product inspection. Third party inspection upon clients request.

DEF Pipeline can provide HDPE high pressure customiazed pipe fittings of various projects and specifications according to ASTM, ISO 4427, EN12201, EN1555 and other standards, with competitive prices high quality and reliable connection.

| Products details information | Company/factory strength | ||

| Product name | High pressure high density polyethylene (HDPE) fittings | Production capacity | 160*40ft containers/month |

| Brand | Def pipeline(or OEM) | Sample | Free sample available |

| Dia. ranges | DN50-2000mm(2 inch-80 inch) | Delivery time | In stock, Quick deliery |

| Pressure class | SDR26 to SDR6; PN6 to PN32 | Quality | QA & QC system, Ensure traceability of each process |

| Raw material | PE100, PE4710, PE3608, PE100RC... | Warranty | 50 years with normal use |

| Application | Drinking water, Fresh water, Drainage, Oil and gas, Mining, Dredging, Marine, Irrigation, Industry, Chemical, Fire fighting... | Test/Inspection | National standard laboratory, Pre-delivery inspection |

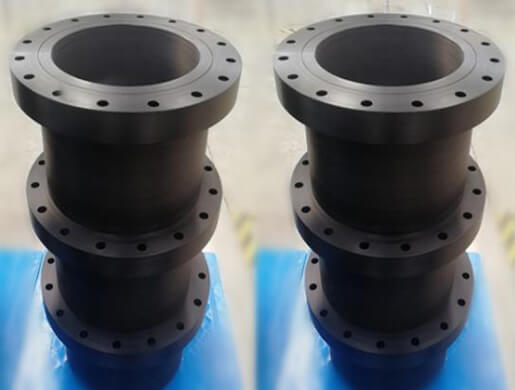

| Category | Concentric reducer, Eccentric reducer, Equal tee, Mud tee, Reducer tee, Flange adaptor/stub End, Spigot end cap, Flanges and HDPE blind flange, HDPE hollow bar, HDPE solid rod, 90 deg elbow, Sweep bends | Certificates | ISO9001, OHSAS 18001, ISO14001, ISO45001, CE... |

| Color | Black, Blueor or others colors | Management | Effective 8S management system |

| Packing | Packaged by cartons or bags | No. of employees | More than 300 |

| Matching products | HDPE Butt fusion welding fitting, Socket fusion, Electro fusion welding fitting, Compression fittings, Welding machines and tools, etc. | Service | Research, Design, Sales, Solution providing, Test, Manufacture, Aftersales service |

Customers are welcome to visit the factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com. Or (WhatsApp): +86 13298353566.

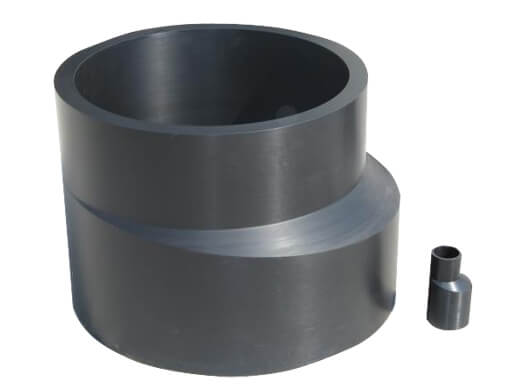

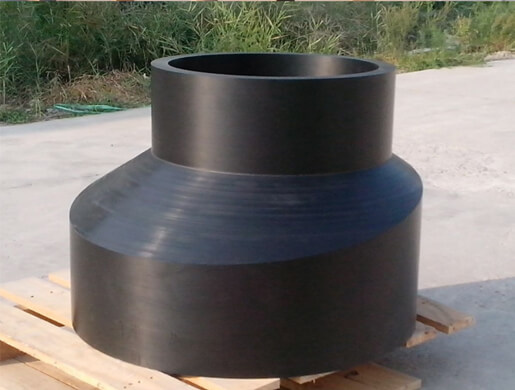

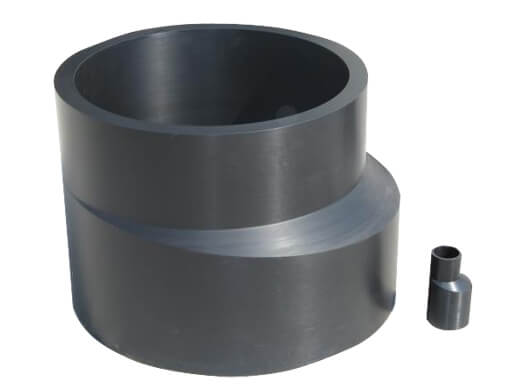

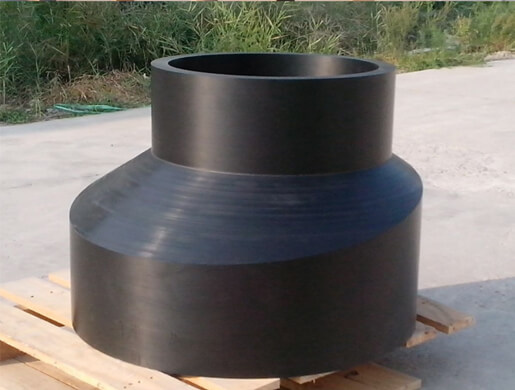

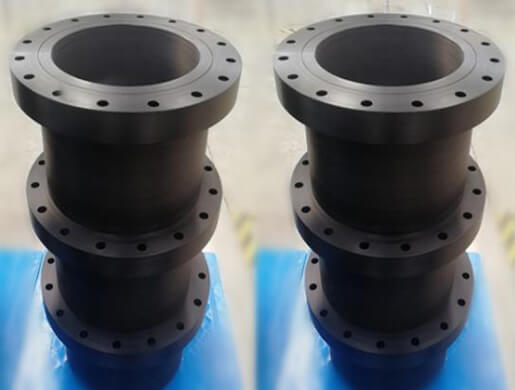

High pressure High Density Polyethylene (HDPE) fittings are made from the thick-walled pipe blanks and bars. The maximum outer diameter of the thick-walled tube blank is 2300mm, and the maximum outer diameter of the bar is 1450mm. Thick-walled pipe blanks and bars can make for various pipe fittings , which are difficult to process by injection molding, so as to solve many problems encountered in the design, construction and installation of PE pipes.

It can be produced and processed according to ASTM, ISO 4427, EN12201, EN1555 and other standards, concentric reducer, eccentric reducer, tee, mud tee, pipe cap flange and other customized pipe fittings, etc., can be customized according to drawings. Range: 50-2000mm, pressure sdr17-sdr6, the pipe fittings produced by our company have been widely used in the field of gas and water supply.

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com. Or (WhatsApp): +86 13298353566.

High Pressure HDPE Fittings(SDR9-SDR6)

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com. Or (WhatsApp): +86 13298353566.

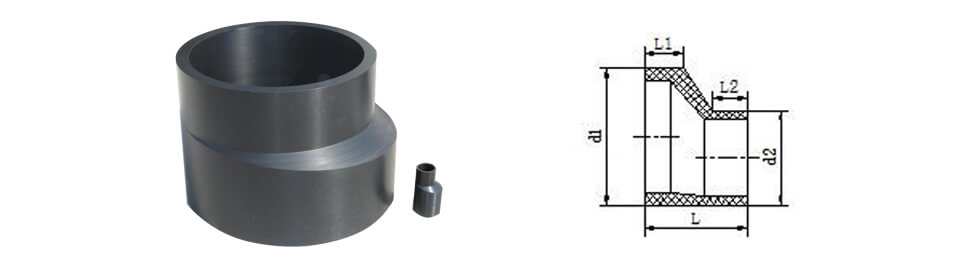

Specification of HDPE Eccentric Reducer SDR9, SDR7.4, SDR6...

| HDPE Eccentric Reducer(SDR17 - SDR6) | ||||||||

| The size of the pipe fitting is formulated by our company according to the actual situation. Other sizes can be customized according to the customer's data. The specifications and non-standard specifications not included in the table, please consult us separately. | ||||||||

| d1*d2 mm | L mm | L1 mm | L2 mm | d1*d2 mm | L mm | L1 mm | L2 mm | |

| 63*32 | 160 | 80 | 50 | 225*75 | 220 | 100 | 90 | |

| 63*40 | 160 | 80 | 50 | 225*90 | 220 | 100 | 90 | |

| 63*50 | 160 | 80 | 50 | 225*110 | 220 | 100 | 90 | |

| 75*32 | 160 | 80 | 50 | 225*125 | 220 | 100 | 90 | |

| 75*40 | 160 | 80 | 50 | 225*140 | 220 | 100 | 90 | |

| 75*50 | 160 | 80 | 50 | 225*160 | 220 | 100 | 90 | |

| 75*63 | 160 | 80 | 50 | 225*180 | 220 | 100 | 90 | |

| 90*40 | 160 | 80 | 50 | 225*200 | 220 | 100 | 90 | |

| 90*50 | 160 | 80 | 50 | 250*75 | 220 | 100 | 90 | |

| 90*63 | 160 | 80 | 50 | 250*90 | 220 | 100 | 90 | |

| 90*75 | 160 | 80 | 50 | 250*110 | 220 | 100 | 90 | |

| 110*63 | 180 | 80 | 70 | 250*125 | 220 | 100 | 90 | |

| 110*75 | 180 | 80 | 70 | 250*140 | 220 | 100 | 90 | |

| 110*90 | 180 | 80 | 70 | 250*160 | 220 | 100 | 90 | |

| 125*63 | 180 | 80 | 70 | 250*180 | 220 | 100 | 90 | |

| 125*75 | 180 | 80 | 70 | 250*200 | 220 | 100 | 90 | |

| 125*90 | 180 | 80 | 70 | 250*225 | 220 | 100 | 90 | |

| 125*110 | 180 | 80 | 70 | 280*110 | 230 | 110 | 90 | |

| 140*63 | 180 | 80 | 70 | 280*125 | 230 | 110 | 90 | |

| 140*75 | 180 | 80 | 70 | 280*140 | 230 | 110 | 90 | |

| 140*90 | 180 | 80 | 70 | 280*160 | 230 | 110 | 90 | |

| 140*110 | 180 | 80 | 70 | 280*180 | 230 | 110 | 90 | |

| 140*125 | 180 | 80 | 70 | 280*200 | 230 | 110 | 90 | |

| 160*63 | 190 | 80 | 80 | 280*225 | 230 | 110 | 90 | |

| 160*75 | 190 | 80 | 80 | 280*250 | 230 | 110 | 90 | |

| 160*90 | 190 | 80 | 80 | 315*110 | 230 | 110 | 90 | |

| 160*110 | 190 | 80 | 80 | 315*125 | 230 | 110 | 90 | |

| 160*125 | 190 | 80 | 80 | 315*140 | 230 | 110 | 90 | |

| 160*140 | 190 | 80 | 80 | 315*160 | 230 | 110 | 90 | |

| 180*63 | 200 | 90 | 80 | 315*180 | 230 | 110 | 90 | |

| 180*75 | 200 | 90 | 80 | 315*200 | 230 | 110 | 90 | |

| 180*90 | 200 | 90 | 80 | 315*225 | 230 | 110 | 90 | |

| 180*110 | 200 | 90 | 80 | 315*250 | 230 | 110 | 90 | |

| 180*125 | 200 | 90 | 80 | 315*280 | 230 | 110 | 90 | |

| 180*140 | 200 | 90 | 80 | 355*110 | 240 | 110 | 100 | |

| 180*160 | 200 | 90 | 80 | 355*125 | 240 | 110 | 100 | |

| 200*63 | 210 | 100 | 80 | 355*140 | 240 | 110 | 100 | |

| 200*75 | 210 | 100 | 80 | 355*160 | 240 | 110 | 100 | |

| 200*90 | 210 | 100 | 80 | 355*180 | 240 | 110 | 100 | |

| 200*110 | 210 | 100 | 80 | 355*200 | 240 | 110 | 100 | |

| 200*125 | 210 | 100 | 80 | 355*225 | 240 | 110 | 100 | |

| 200*140 | 210 | 100 | 80 | 355*250 | 240 | 110 | 100 | |

| 200*160 | 210 | 100 | 80 | 355*280 | 240 | 110 | 100 | |

| 200*180 | 210 | 100 | 80 | 355*315 | 240 | 110 | 100 | |

| 400*110 | 240 | 110 | 100 | 630*560 | 260 | 120 | 110 | |

| 400*125 | 240 | 110 | 100 | 710*250 | 270 | 130 | 110 | |

| 400*140 | 240 | 110 | 100 | 710*280 | 270 | 130 | 110 | |

| 400*160 | 240 | 110 | 100 | 710*315 | 270 | 130 | 110 | |

| 400*180 | 240 | 110 | 100 | 710*355 | 270 | 130 | 110 | |

| 400*200 | 240 | 110 | 100 | 710*400 | 270 | 130 | 110 | |

| 400*225 | 240 | 110 | 100 | 710*450 | 270 | 130 | 110 | |

| 400*250 | 240 | 110 | 100 | 710*500 | 270 | 130 | 110 | |

| 400*280 | 240 | 110 | 100 | 710*560 | 270 | 130 | 110 | |

| 400*315 | 240 | 110 | 100 | 710*630 | 270 | 130 | 110 | |

| 400*355 | 240 | 110 | 100 | 800*315 | 280 | 130 | 120 | |

| 450*200 | 250 | 120 | 100 | 800*355 | 280 | 130 | 120 | |

| 450*225 | 250 | 120 | 100 | 800*400 | 280 | 130 | 120 | |

| 450*250 | 250 | 120 | 100 | 800*450 | 280 | 130 | 120 | |

| 450*280 | 250 | 120 | 100 | 800*500 | 280 | 130 | 120 | |

| 450*315 | 250 | 120 | 100 | 800*560 | 280 | 130 | 120 | |

| 450*355 | 250 | 120 | 100 | 800*630 | 280 | 130 | 120 | |

| 450*400 | 250 | 120 | 100 | 800*710 | 280 | 130 | 120 | |

| 500*200 | 260 | 120 | 110 | 900*315 | 290 | 140 | 120 | |

| 500*225 | 260 | 120 | 110 | 900*355 | 290 | 140 | 120 | |

| 500*250 | 260 | 120 | 110 | 900*400 | 290 | 140 | 120 | |

| 500*280 | 260 | 120 | 110 | 900*450 | 290 | 140 | 120 | |

| 500*315 | 260 | 120 | 110 | 900*500 | 290 | 140 | 120 | |

| 500*355 | 260 | 120 | 110 | 900*560 | 290 | 140 | 120 | |

| 500*400 | 260 | 120 | 110 | 900*630 | 290 | 140 | 120 | |

| 500*450 | 260 | 120 | 110 | 900*710 | 290 | 140 | 120 | |

| 560*200 | 260 | 120 | 110 | 900*800 | 290 | 140 | 120 | |

| 560*225 | 260 | 120 | 110 | 1000*400 | 300 | 140 | 130 | |

| 560*250 | 260 | 120 | 110 | 1000*450 | 300 | 140 | 130 | |

| 560*280 | 260 | 120 | 110 | 1000*500 | 300 | 140 | 130 | |

| 560*315 | 260 | 120 | 110 | 1000*560 | 300 | 140 | 130 | |

| 560*355 | 260 | 120 | 110 | 1000*630 | 300 | 140 | 130 | |

| 560*400 | 260 | 120 | 110 | 1000*710 | 300 | 140 | 130 | |

| 560*450 | 260 | 120 | 110 | 1000*800 | 300 | 140 | 130 | |

| 560*500 | 260 | 120 | 110 | 1000*900 | 300 | 140 | 130 | |

| 630*200 | 260 | 120 | 110 | 1200*450 | 310 | 150 | 130 | |

| 630*225 | 260 | 120 | 110 | 1200*500 | 310 | 150 | 130 | |

| 630*250 | 260 | 120 | 110 | 1200*560 | 310 | 150 | 130 | |

| 630*280 | 260 | 120 | 110 | 1200*630 | 310 | 150 | 130 | |

| 630*315 | 260 | 120 | 110 | 1200*710 | 310 | 150 | 130 | |

| 630*355 | 260 | 120 | 110 | 1200*800 | 310 | 150 | 130 | |

| 630*400 | 260 | 120 | 110 | 1200*900 | 310 | 150 | 130 | |

| 630*450 | 260 | 120 | 110 | 1200*1000 | 310 | 150 | 130 | |

| 630*500 | 260 | 120 | 110 | |||||

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com. Or (WhatsApp): +86 13298353566.

Def Pipeline invests a lot of money in product research and development and technological innovation every year to implement modern manufacturing processes, improve production efficiency and service quality to ensure that DEF is always in the leading position in the industry. Def Pipeline pays attention to the innovation of products and the durability of service life in the design and development. We pay attention to the safety of the production process and the precision of processing in the production process. And pays attention to excellence and high-end product quality in the inspection process. Def Pipeline focuses on the future needs of the market. With our rich product portfolio of HDPE pipe & fittings and professional technical knowledge, Def Pipeline provides product technical and price support at every customer project stage. Def Pipeline helps customers make the plan to reduce the procurement cost and installation costs reasonably.

Please send email to: jolin@defpipe.com. Or (WhatsApp): +86 13298353566.

High Pressure HDPE fittings SDR9, SDR7.4, SDR6...

The following are the specifications of High Pressure HDPE fittings of different standards. Technical parameters, pictures and technical brochure as below for online preview and download.

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com. Or (WhatsApp): +86 13298353566.