Connecting the wor1d with quality

+86 132 9835 3566Call to get professional solutions for you pipeline projects

Call to get professional solutions for you pipeline projects

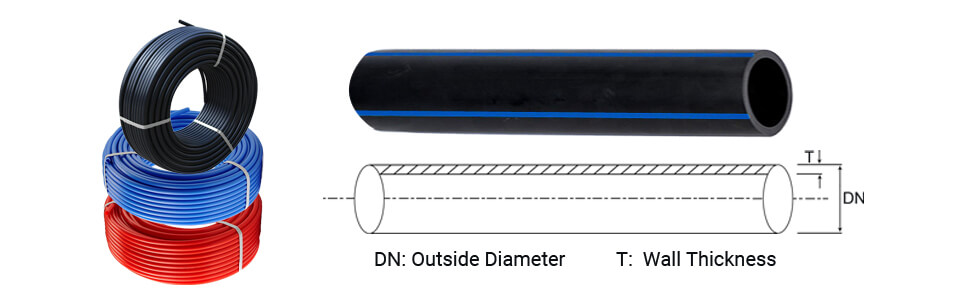

1. Dia: DN20-2000mm (1/2 inch-80 inch).

2. Pressure Class: SDR41, SDR33, SDR26, SDR21, SDR17, SDR13.6, SDR11, SDR9, SDR7.4, SDR6.

3. Pressure Class: PN4, PN5, PN6, PN8, PN10, PN12.5, PN16, PN20, PN25, PN32.

4. Packing: 11.8m, 11.9m, 5.8m, or 5.9m/pcs for straight, 100-200m by coils for DN20-90mm.

5. Delivery: 5-10 days depending on the total quantity.

6. Product inspection: Raw material inspection. Finished product inspection. Third party inspection upon clients request.

| Products details information | Company/factory strength | ||

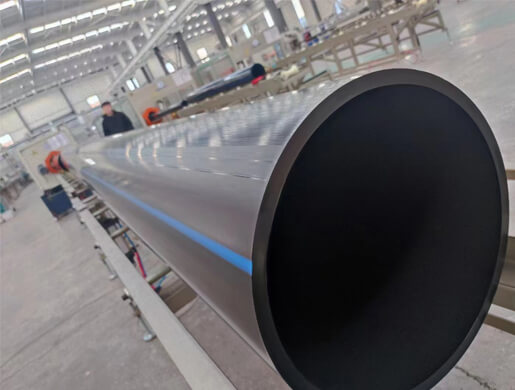

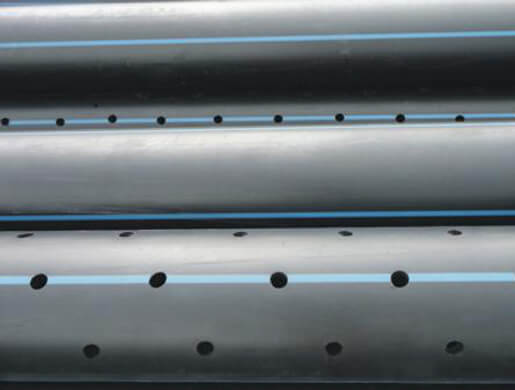

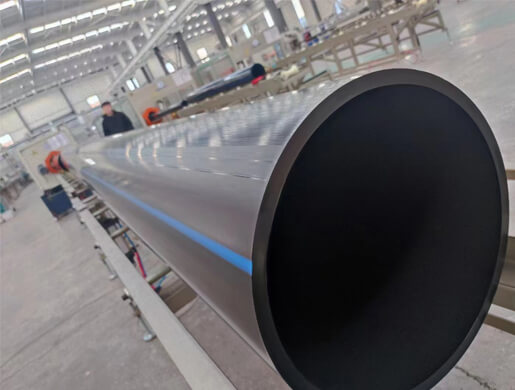

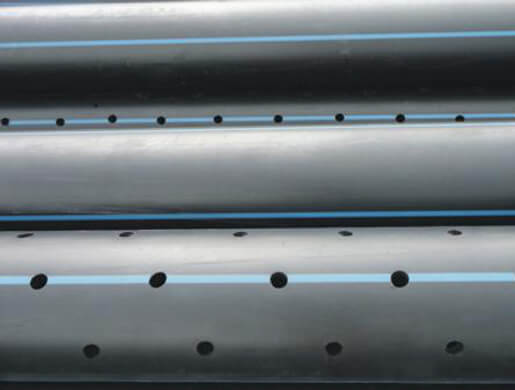

| Product name | High Density Polyethylene (HDPE) perforated drain pipe and fitting | Production capacity | 160*40ft containers/month |

| Brand | Def pipeline(or OEM) | Sample | Free sample available |

| Dia. ranges | DN20-2000mm(1/2 inch-80 inch) | Delivery time | 5-10 days, depending on the quantity |

| Pressure class | SDR41 to SDR6; PN4 to PN32 | Test/inspection | National standard laboratory, Pre-delivery inspection |

| Standards | ISO 4427, ASTM 3035, ASTM F714, EN12201, AS/NZS4130, DIN8074, GOST18599, DIPS | Certificates | ISO9001, OHSAS 18001, ISO14001, ISO45001, CE... |

| Raw material | PE80, PE100, PE4710, PE3608... | Management | Effective 8S management system |

| Color | Black with blue stripes, Black or others colors | Warranty | 50 years with normal use |

| Packing | 5.8m or 11.8m/length (customizable) | Quality | QA & QC system, Ensure traceability of each process |

| Application | Waste water drainage, Mining, Chemical, Sewer, Leachate, Landfill... | No. of employees | More than 300 |

| Matching products | HDPE Butt fusion welding fitting, Socket fusion, Electro fusion welding fitting, Compression fittings, Welding machines and tools, etc. | Service | Research, Design, Sales, Solution providing, Test, Manufacture, Aftersales service |

Customers are welcome to visit the factory or conduct a third-party audit.

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com Or (WhatsApp): +86 13298353566.

PE perforated pipe is a new type pipe with water filtration (drainage) function. It is used for vertical and horizontal drainage and water permeation of expressways, drainage of tunnels and underground passages, municipal engineering, water purification plants, sewage plants, garbage dumps, and gardens, water absorption, permeation and drainage of underground drainage projects. It will not be broken due to changes in geology and geographic temperature, and will not cause pollution to the environment.

HDPE fittings

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com Or (WhatsApp): +86 13298353566.

Specifications of High Density Polyethylene (HDPE) Perforated Drain Pipe

| ISO 4427 Pipe Series | S 16 | S 12,5 | S 10 | S 8 | S 6,3 | S 5 | S 4 | S 3.2 | |

| ASTM F714 SDR | SDR 33 | SDR 26 | SDR 21 | SDR 17 | SDR 13.6 | SDR 11 | SDR 9 | SDR 7.4 | |

| Nominal Pressure PE 100 | PN5 | PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | PN25 | |

| Nominal Size DN (mm) | Equiv Size (in) | Wall Thickness(mm) | |||||||

| 16 | 2 | 2.3 | |||||||

| 20 | 0.79 | 1.5 | 2 | 2.3 | 3 | ||||

| 25 | 0.98 | 0.76 | 0.8 | 1.2 | 1.5 | 2 | 2.3 | 3 | 3.5 |

| 32 | 1.26 | 0.97 | 1 | 1.5 | 2 | 2.4 | 3 | 3.6 | 4.4 |

| 40 | 1.57 | 1.21 | 1.2 | 2 | 2.4 | 3 | 3.7 | 4.5 | 5.5 |

| 50 | 1.97 | 1.52 | 2 | 2.4 | 3 | 3.7 | 4.6 | 5.6 | 6.9 |

| 63 | 2.48 | 1.91 | 2.5 | 3 | 3.8 | 4.7 | 5.8 | 7.1 | 8.6 |

| 75 | 2.95 | 2.27 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | 10.3 |

| 90 | 3.54 | 2.73 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | 12.3 |

| 110 | 4.33 | 3.33 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 | 15.1 |

| 125 | 4.92 | 3.79 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 | 17.1 |

| 140 | 5.51 | 4.24 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | 19.2 |

| 160 | 6.3 | 4.85 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | 21.9 |

| 180 | 7.09 | 5.45 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | 24.6 |

| 200 | 7.87 | 6.06 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | 27.4 |

| 225 | 8.86 | 6.82 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | 30.8 |

| 250 | 9.84 | 7.58 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | 34.2 |

| 280 | 11.02 | 8.48 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | 38.3 |

| 315 | 12.4 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 | 43.1 |

| 355 | 13.98 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 | 48.5 |

| 400 | 15.75 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 | 54.7 |

| 450 | 17.72 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 | 61.5 |

| 500 | 19.69 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 | 67.6 |

| 560 | 22.05 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 | 75.7 |

| 630 | 24.8 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 | 85.1 |

| 710 | 27.95 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 | 95.9 |

| 800 | 31.5 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 | |

| 900 | 35.43 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | ||

| 1000 | 39.37 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | ||

| 1200 | 47.24 | 36.7 | 45.9 | 57.2 | 67.9 | 88.2 | |||

| 1400 | 55.12 | 42.9 | 53.5 | 66.7 | 82.4 | 102.9 | |||

| 1600 | 62.99 | 61.2 | 76.2 | 94.1 | 117.6 | ||||

| 1800 | 70.86 | 69.1 | 85.7 | 105.9 | |||||

| 2000 | 78.74 | 76.9 | 95.2 | 117.6 | |||||

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com Or (WhatsApp): +86 13298353566.

Def Pipeline invests a lot of money in product research and development and technological innovation every year to implement modern manufacturing processes, improve production efficiency and service quality to ensure that DEF is always in the leading position in the industry. Def Pipeline pays attention to the innovation of products and the durability of service life in the design and development. We pay attention to the safety of the production process and the precision of processing in the production process. And pays attention to excellence and high-end product quality in the inspection process. Def Pipeline focuses on the future needs of the market. With our rich product portfolio of HDPE pipe & fittings and professional technical knowledge, Def Pipeline provides product technical and price support at every customer project stage. Def Pipeline helps customers make the plan to reduce the procurement cost and installation costs reasonably.

Please send email to: jolin@defpipe.com Or (WhatsApp): +86 13298353566.

High Density Polyethylene (HDPE) Perforated Drain Pipes and Fitting

The following are the specifications of High Density Polyethylene (HDPE) Perforated Drain Pipe and Fittings of different standards. Technical parameters, pictures and technical brochure as below for online preview and download.

Welcome to contact us for products details and professional service.

Please send email to: jolin@defpipe.com Or (WhatsApp): +86 13298353566.