Connecting the wor1d with quality

+86 132 9835 3566Call to get professional solutions for you pipeline projects

Call to get professional solutions for you pipeline projects

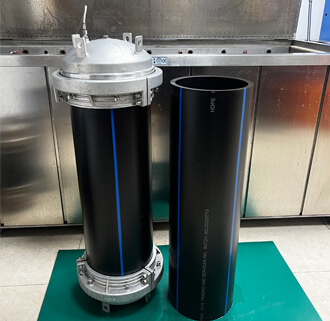

Def Pipeline Being a quality-conscious organization, we maintain a total quality system in our production and the marketing process. Stringent quality checks are conducted at every stage, from sourcing quality raw material to packaging till the delivery of the product.

With many years of extrusion and injection molding experience, Def is the market leader and pioneer in the manufacture of plastic piping systems in China. Our quality control system is as below:

Test of the raw materials

Strict control of production equipment

Inspection and testing of the production process

Inspection and testing of finished products

Top-quality raw materials are a prerequisite for the production of top-quality piping systems. Def pipeline uses top-quality raw materials from world-renowned factories. The excellent performance and stability of these materials have established the high-quality position of Def pipes and fittings in the market.Def use raw materials approved by PE100+ Association. The PE100+ Association ensures the highest quality of PE 100 products by continuously monitoring three essential attributes:

Def equipped with the world’s advanced extrusion production lines and injection molding machines, such as Buttonhead and Krauss Maffei extruders, with high production efficiency and good stability.The euipment has a memory function and a high level of automation to ensure stable pipe quality.

Well-trained and qualified employees are very important. Most of Def’s workers are experts with more than 10 years experience in producing plastic pipes and fittings in China. They can timely and accurately identify the main manufacturing defects in the production process, so as to avoid substandard products in the market in time.

Pre-production samples from our quality assurance department are tested by laboratory technicians:

Mass line production is only possible if the best test results are achieved.

After all tests and inspections comply with the prescribed procedures, the finished product will be put into storage. The inspection content of the finished product:

Def Pipeline has the complete operating process in raw material procurement, finished product manufacturing, sampling inspection, packaging ,delivery and transportation. To ensure that every product delivered to customers must be qualified, safe and stable.